Syringes

If you are looking for manual or pneumatic dispensing of your product in a smaller quantity, syringes are an excellent solution - and it is easy to be accurate in the application, with excellent control over the flow rate of the product.

We repackage chemicals, fluids and greases with state-of-the-art technology and a safety-critical approach. The smallest size that we can repack greases into, for example, is a 30ml syringe, though we also regularly put them into 450ml, 1l and 5l containers.

To ensure that you receive the right product, we always retain a batch sample until the product's expiry date for regulatory purposes. If there is ever an issue from your end as the consumer with what you have received, this protects you as we will be able to refer back to what we had sent. Our operatives perform a visual check on all drums with product to be decanted to ensure for no debris or foreign objects, before repacking.

We also repack adhesives for Sulver. If you have any special requirements or requests, please get in touch with Customer Services and we can discuss your needs.

Our competitive pricing and quick service turnaround sets us out even further as the premier choice in the industry.

If you are looking for manual or pneumatic dispensing of your product in a smaller quantity, syringes are an excellent solution - and it is easy to be accurate in the application, with excellent control over the flow rate of the product.

You may need a reasonable amount of product, but without over 200 litres of excess. If we decant into a smaller can or container, you will get what you need without the shelf life or storage implications of having too much.

For a controlled and consistent spray pattern, you may wish to consider repacking into a trigger spray bottle. They maintain your workers' hygiene by reducing direct contact with the liquid and the surface being treated.

FP1 and FP2 are used frequently used for oil repackaging, specifically for mineral and synthetic oils. These versatile packaging solutions ensure that the oils are stored, handled and worked upon safely, maintaining their quality and performance standards.

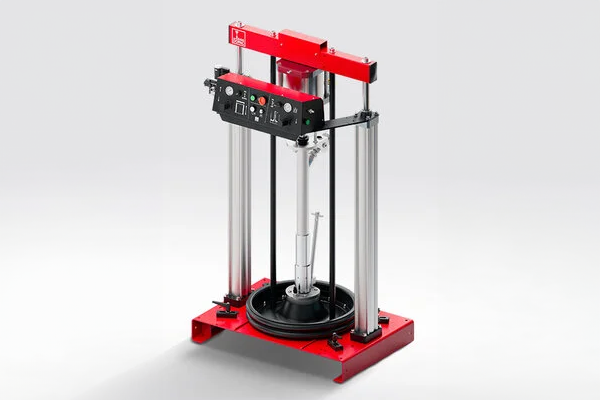

We are excited about the recent acquisition of new machinery, which, once installed, will make our oil repackaging system even smoother. This state-of-the-art equipment will enhance efficiency, reduce turnaround times, and further ensure the high quality and precision of our repackaging services.

Our Technical Account Managers can also help you determine the optimal packaging solution for your application, obtain samples and develop prototypes. If you have a unique application not addressed by the options provided, please use the form below.