3M Corrosion Prevention Sealing Tape 9143FR

- Easy removal with little to no residue

- Excellent corrosion resistance

- Exceptional shop handling

- Ideal for direct to metal subfloor corrosion protection

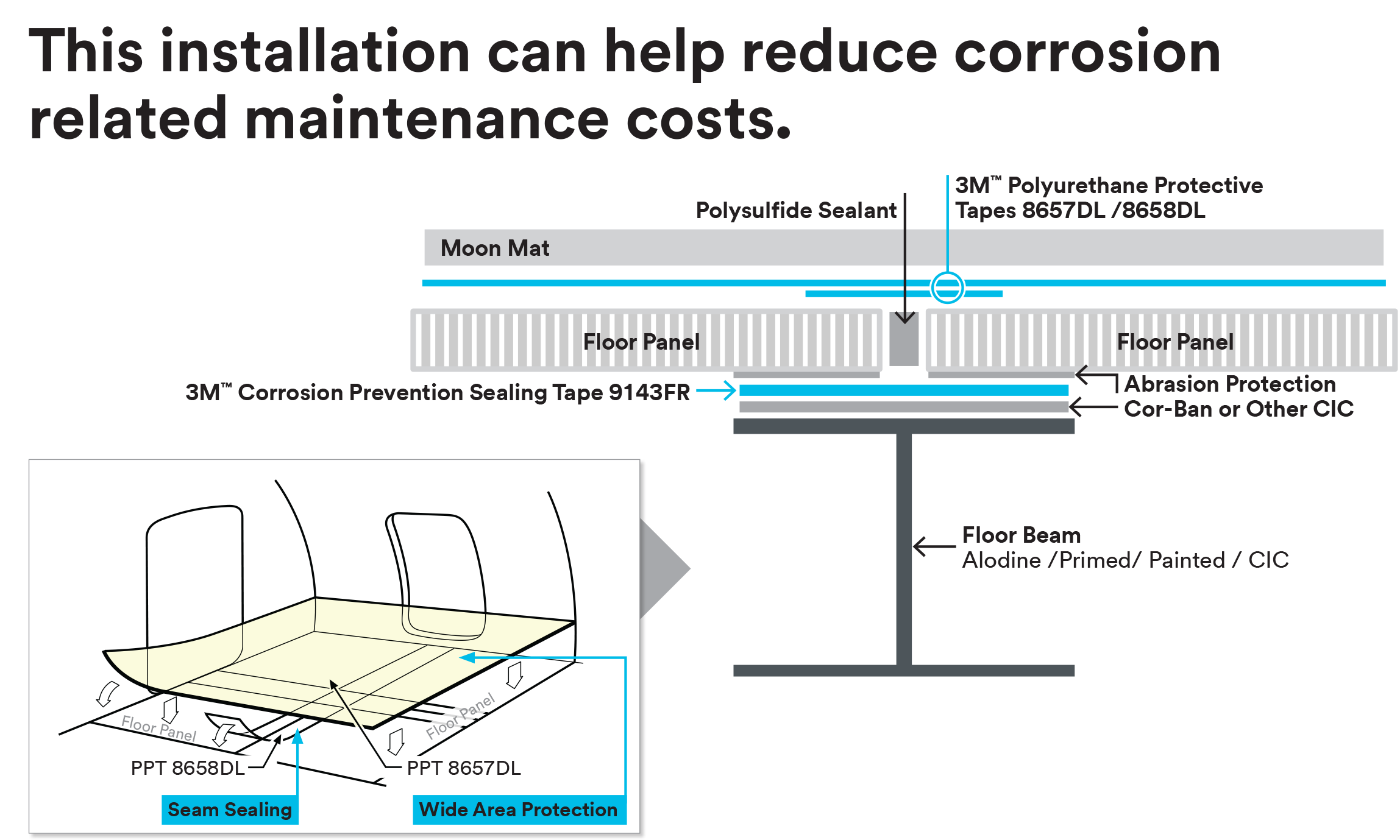

The floors of aircraft entryways, galleys, lavatories and cargo compartments are vulnerable to frequent sources of moisture. Fluids from spills and leaks can migrate into the underlying floor support system, and condensation can form on sub-floor structures which can lead to corrosion. The resulting corrosion damage can weaken the entire sub-floor structure and result in costs up to $100,000 per aircraft, in addition to downtime. 3M protective tape solutions, including Aircraft Interior Corrosion Prevention and Protective Tapes, are designed to help reduce maintenance costs and increase service life of aircraft interior floor systems.

In aerospace engineering, corrosion is the gradual destruction of the surface through the formation of iron oxide (rust) due to exposure to natural elements such as moisture and humidity. While liquid corrosion inhibitive coatings (CIC) are still widely used on the aircraft structure, polyurethane tapes are perfect for seam sealing and wide area protection inside the aircraft. Within aircraft 'wet areas' such as galleys and lavatories, there is a risk of moisture seeping through to the floor beam structure. Aluminium beams used in aircraft flooring are particularly susceptible to corrosive damage, and repairs can cost thousands of pounds a time. The 3M tapes available offer durability, conformability and puncture resistance, while meeting the FAA’s flammability test configuration standards for 14CFR 25.853(a).

Polysulfide sealant and corrosion preventatives are also available from Silmid.