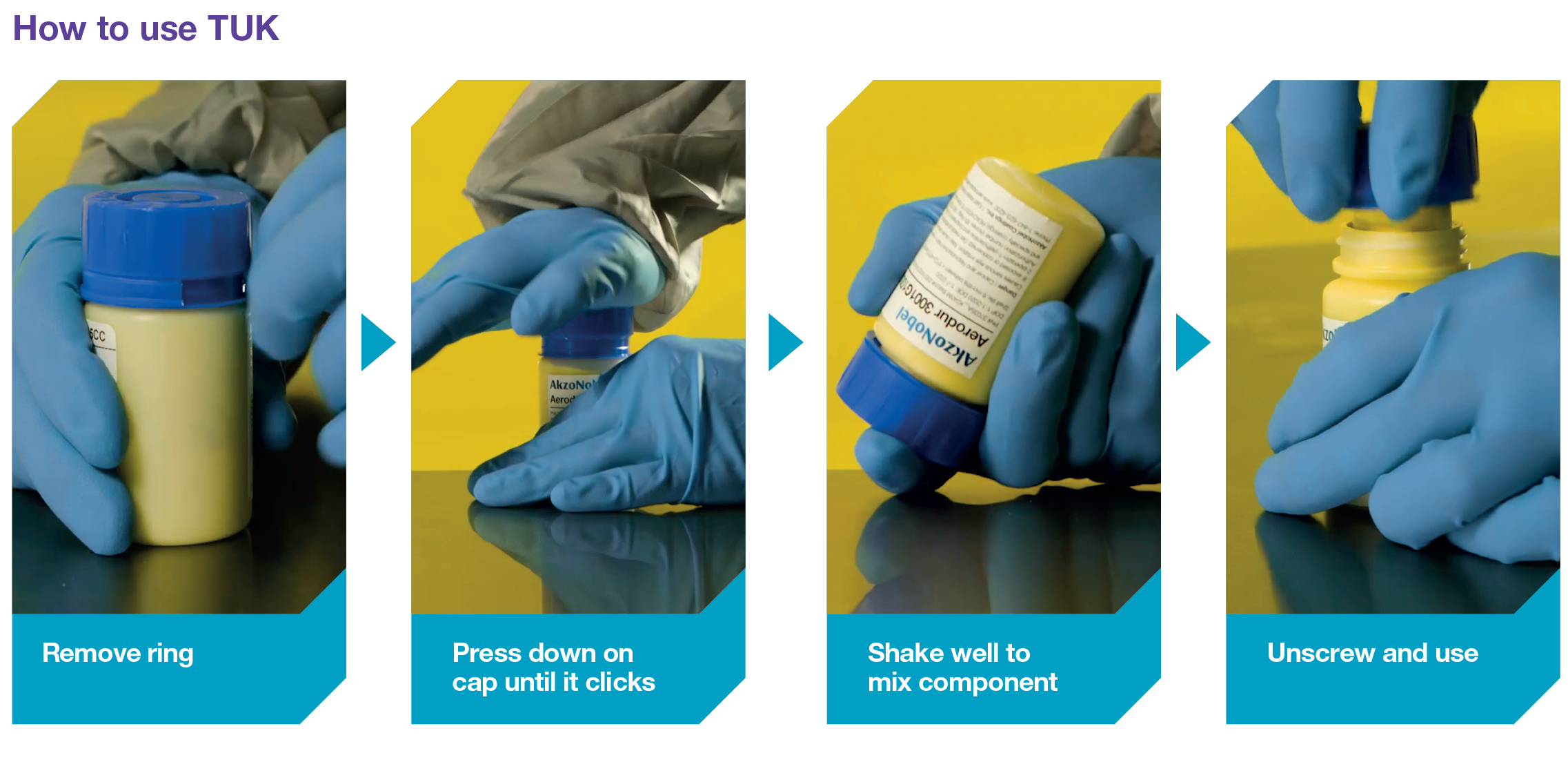

TUK comprises a ready-to-mix base and hardener in two separate compartments, encapsulated into a single plastic container. The user simply removes the ring on the cap of the container and presses it down until it clicks. After shaking to ensure the base and the hardener are properly mixed, the cap can be unscrewed, and the coating is ready to apply. AkzoNobel’s new regular TUKs hold between 30-45ml whereas its mini-TUKs can hold as little as 8ml (up to 20ml), depending on the product mixing ratio.

The new TUK is guaranteed to have the high level of quality that AkzoNobel users demand, and is manufactured and tested in line with their stringent quality control procedures. With short lead times and low minimum order quantities, TUK provides a fast, high quality solution to reduce AOG time and keep your production line rolling.

.png)