Advantages

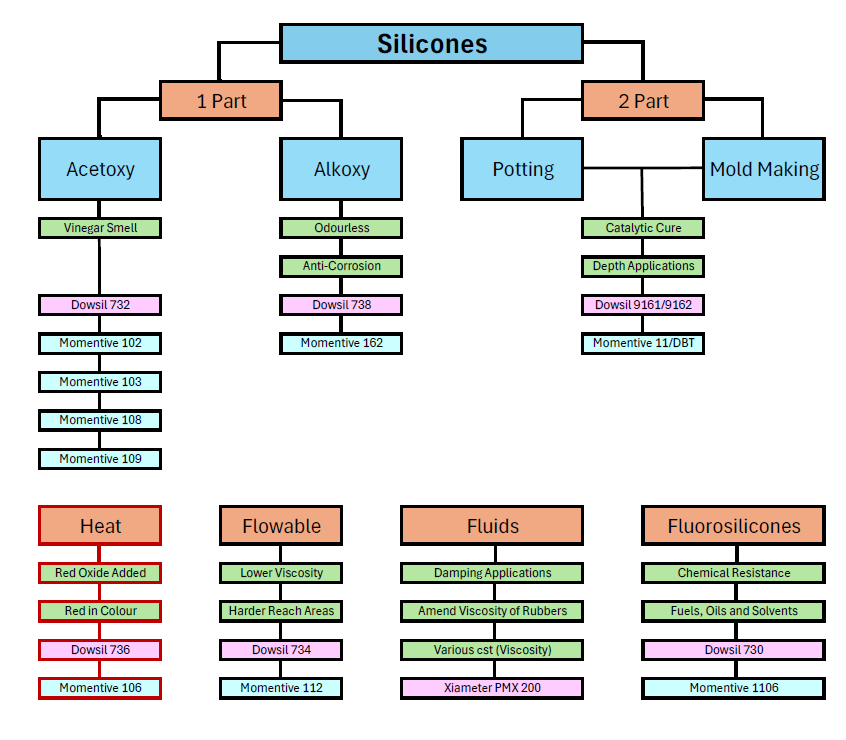

Although there are a wide variety of this type of silicone sealant, and not all advantages are universal, we will explore the advantageous possibilities if selecting the matching RTV silicone.

Ease of Use (room temperature curing abilities)

RTV silicones cure without the need for ovens or specialised curing equipment, making them easy to use in a variety of environments. No Mixing Required: Some RTV silicones come in a one part formulation, eliminating the need for mixing. Fast Cure: Some varieties cure within hours, allowing for quick assembly and application.

Durability

Heat Resistance: Many RTV silicones are heat-resistant, making them suitable for high-temperature applications. They can withstand a wide temperature range, from as low as -60°C to over 250°C in some cases. This makes them suitable for environments exposed to extreme temperatures. Chemical Resistance: RTV silicones are often resistant to a variety of chemicals, including oils, fuels, and mild acids and bases. Weather Resistance: RTV silicones are typically weather-resistant.

Performance

Dimensional Stability: RTV silicones exhibit excellent dimensional stability, making them ideal for applications where precise tolerances are required.

Flexibility: RTV silicones are flexible, allowing them to absorb vibrations and accommodate movement. Low Shrinkage: They have minimal shrinkage during curing, which ensures that the form, fit, and seal are maintained after application.

Safety

Non-Toxic: Many RTV silicones are non-toxic and safe for use in applications where contact with humans or animals is possible. They can also be safe as food-grade silicones used in kitchens or medical settings.

Versatility

Wide Range of Applications: RTV silicones can be used for a variety of purposes, including-

Moulding and Casting: RTV silicones are used for creating detailed moulds due to their flexibility and ability to capture fine detail.

Sealants and Adhesives: Common in the construction and automotive industries as they provide both sealing and bonding capabilities.

Medical and Food-Grade Options: Some RTV silicones are FDA approved for use in medical and food-related applications.

Customisable Properties: The properties of RTV silicones can be tailored to specific requirements by selecting different formulations.