Visitor Options

Sign in / Register Account And Quick Order

0 Basket

Please note - Silmid will be closed on Friday, 18th April 2025 and Monday, 21st April 2025 for the Easter Bank Holiday. We will reopen as usual on Tuesday, 22nd April 2025. Thank you for your continued support.

The Semkit® package assures accurate proportioning of the materials since the pre-measured components are stored in separate compartments within the cartridge. It eliminates the labour-intensive tasks of measuring and handling materials while minimizing skin contact and material fumes. All the material contained inside the two-component Semkit® package is mixed within the cartridge and can be extruded with virtually nothing remaining. This configuration provides added value by eliminating material exposure and contamination, dramatically reducing waste, and ensuring the correct ratio of each material is used in every application.

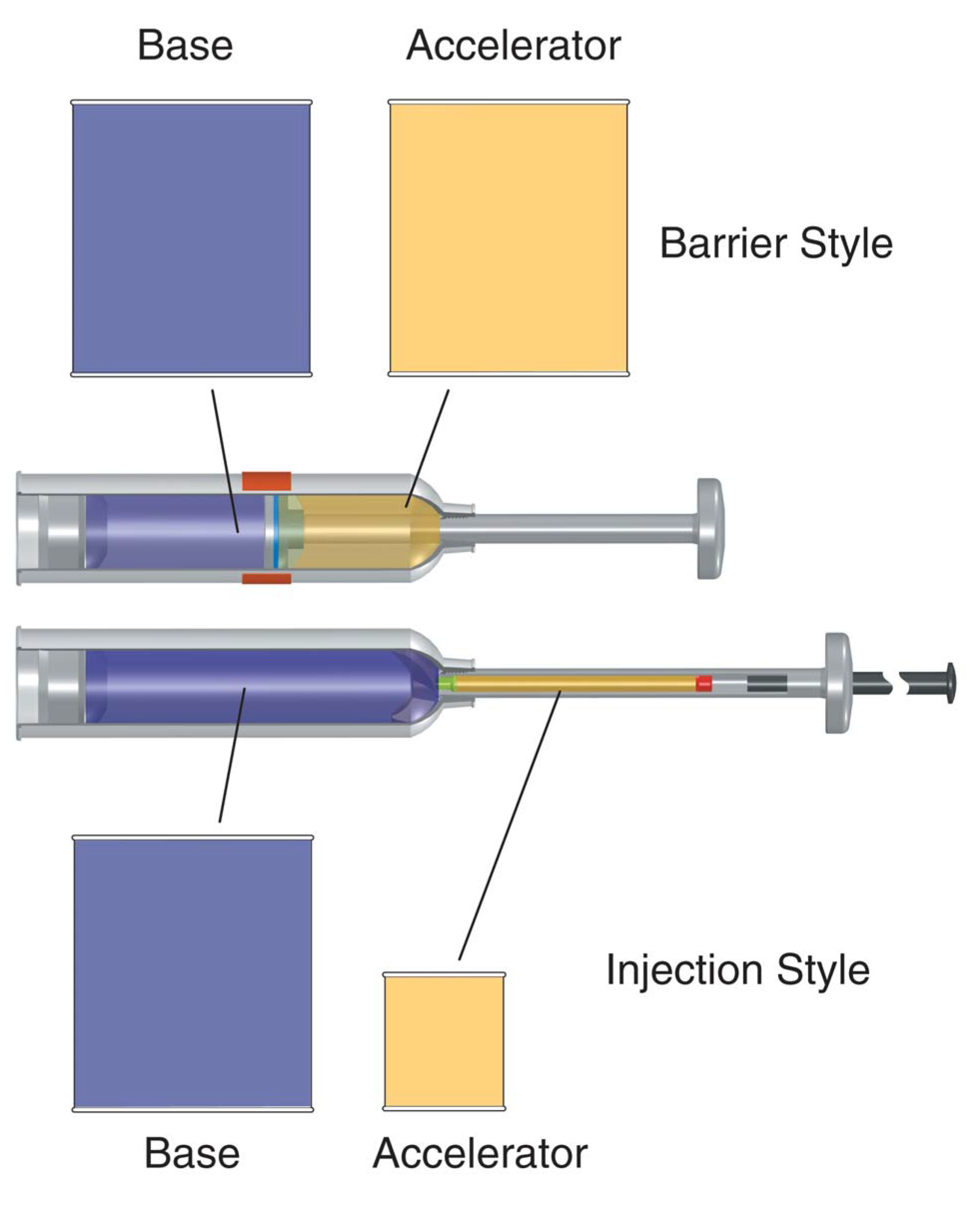

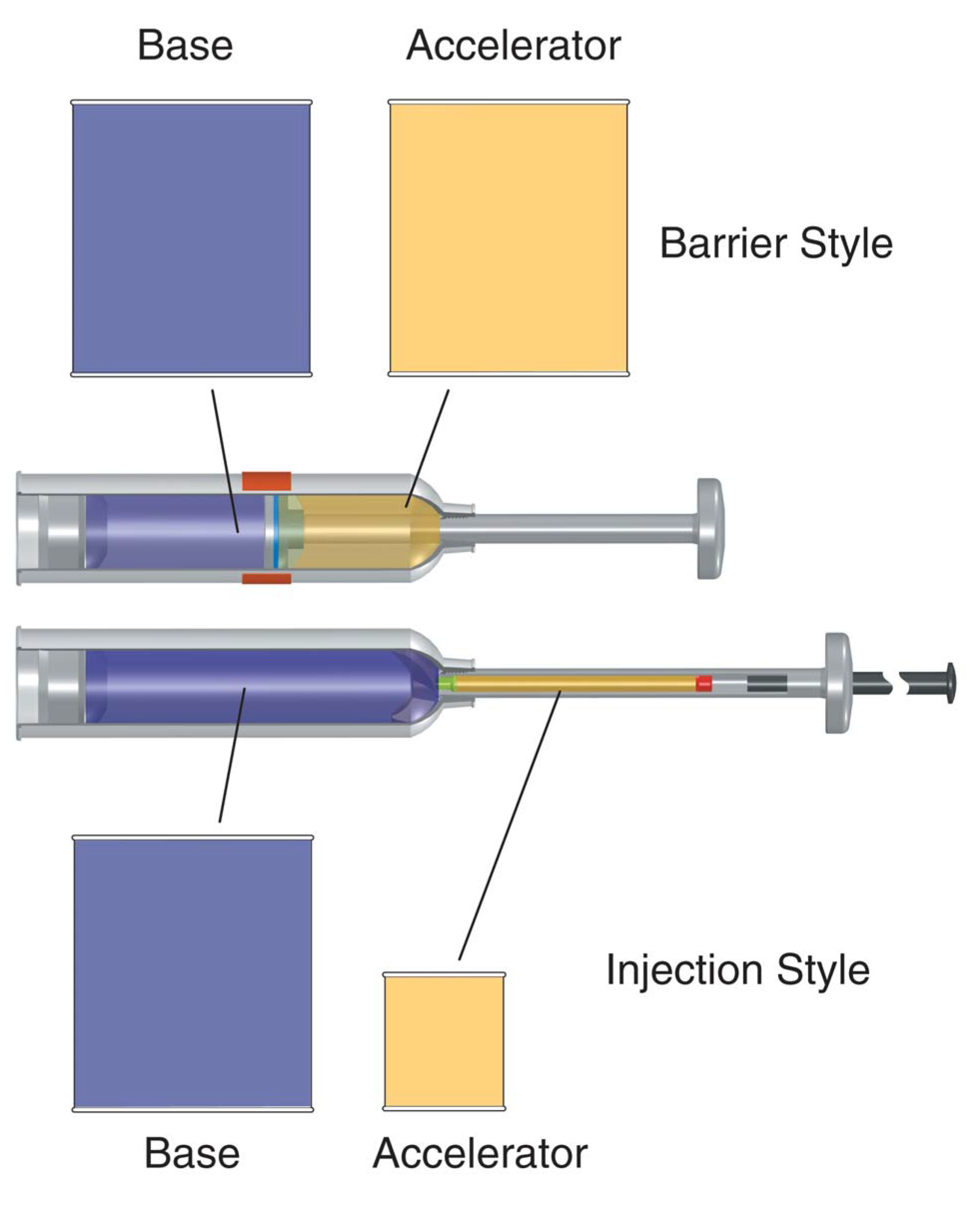

There are two styles of Semkit® packages: injection and barrier. Injection kits are typically used with mix ratios of 10:1 or higher. In this kit, the base material is contained in the cartridge, while the catalyst is stored inside the injection rod. The most popular styles are informally referred to as 654 (6oz Injection Style Cartridge with rod) and 655 (2.5oz Injection Style Cartridge with rod). Barrier style kits are typically used with mix ratios of 1:1 to 10:1. Both materials are contained in the cartridge and are separated by a foil barrier.

Operators can mix the kit manually, semi-automatically, or automatically, with a range of options discussed further in our article library. It can then be fitted with a special nozzle and placed in a Semco® pneumatic or manual dispensing gun. After application, the nozzle and kit are disposable, reducing labour and production costs.